I’ve been back home more than two weeks and I’ve struggled to get out this blog post. Everything I experienced in Tennessee now feels like bunched up laundry in a bag and I’m trying to dig through it to find specific pieces. Is there a theme I can work with? What stories are worth telling? What is the overall feeling I came away with?

I think I need to start with this picture of my first piece of sawn lumber:

Standard measurements weren’t my concern as much as cutting something square.

My whole trip felt like it was leading up to this yet it wasn’t until the last two days that I got it together to actually try out my new equipment.

The Alaskan Mill came in a flat box and I put it together a few days later. For the next two weeks the bulky metal frame sat on Aunt Linda’s living room floor while I got my thoughts and courage together.

To call this product a mill is a bit of a misnomer. As a noun, the word means a place where things are cut. It goes without saying that the place has to have the machinery to do the cutting. In this case the mill houses the chainsaw and guides it through timber.

I’d finally gotten comfortable using my smaller chainsaw. Now I’d purchased one twice as powerful and I was going to attach it to this apparatus that together would make it all weigh close to forty pounds.

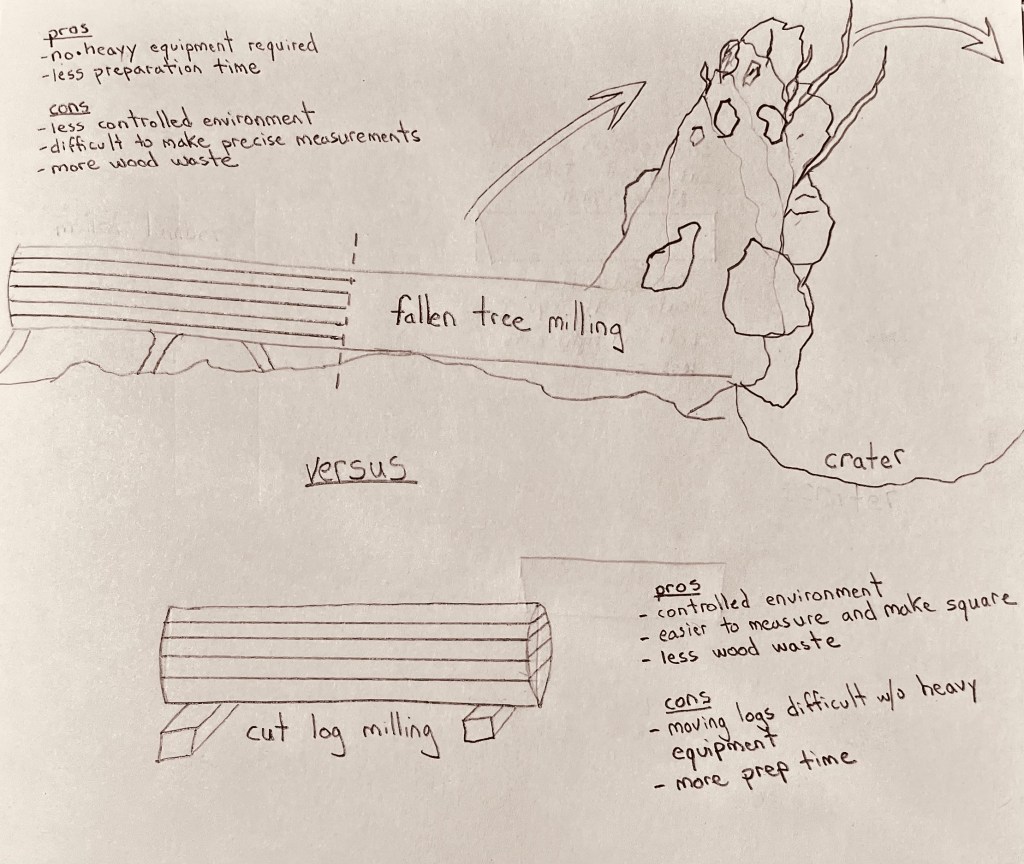

No single Youtube video answered all my questions about using the mill. Most showed people milling sectioned logs, but I wanted to mill directly off the fallen trees. My thought was that cutting a log, then moving and lifting it onto a level platform would be a difficult waste of time.

I ordered a cheap companion mill—a Timber Tuff guide—to square the sides of the downed trees with vertical cuts rather than using the Alaskan Mill which would require turning the log.

It was a lengthy learning process making my first piece of lumber. With experience it might have taken just ten minutes. It took me three hours.

This hundred foot White pine came down sometime after my last trip to Tennessee in January. It was right next to the pine that I cut into a bridge three years ago. I started milling at the other end.

I first cleaned up the end cutting off branches and clearing the area around it.

I used a draw knife to cut the bark. This may have been an unnecessary step but it reduced the sticky sap being slung everywhere during sawing .

My first cut was too deep but it prepared a level surface for making subsequent edge cuts and the next horizontal plank cut.

My single piece of lumber was milled off this.

Why That First Piece of Lumber Took So Long to Mill

*I practiced putting the chainsaw in the Alaskan Mill before leaving home, but this had to be relearned in the field.

*The countersink on my drill bit was not sinking and I didn’t have the right size allen wrench to tighten it. (My chosen guide system uses planks attached to the log. You can also use rail kits designed for these mills or an aluminum ladder.)

*I lost the allen wrench I ended up borrowing from a neighbor and kept stopping to look for it in the same places I’d already checked five times. It eventually turned up in the little watch pocket in my jeans. (When I’m working I try to remember where I put things by repeating it to myself. For example, Machete stuck in ground next to leaning tree. Machete stuck in ground next to leaning tree. Sometimes it works; sometimes my little haiku just turns into rhythmic sounds that fifteen minutes later are a distant memory. In this case I never said, Allen wrench in little watch pocket. Allen wrench in little watch pocket.)

*I only had one screw gun and was constantly changing between using a drill bit and a star bit.

*I was stuck using the scrench (screwdriver/wrench) that came with the mill so every time I had to adjust the mill or move the chainsaw from the Alaskan to the Timber Tuff I had to do the old scrench on, scrench off dance.

*I screwed down the guide plank to use again after the log was squared. (Once the log is flat on top that becomes the guide for more horizontal cuts.)

*More dancing—the measuring marks on the Alaskan are very hard to read causing me to do the ole glasses on, glasses off. (I may try to paint some enamel into the debossed marks on the metal to see it better.)

The next day things went faster when I started working on the fallen oak on the other piece of land. That morning I drove into Halls and bought a set of allen wrenches, another screw gun—an impact driver for versatility—and a ratchet and socket set. Having the correct tools is sometimes half the

battle—when it isn’t all of it.

There was no reason for me to move from the pine tree to the oak to do more milling. There was still plenty of pine tree left. I simply wanted to try the new chainsaw and mills on the harder wood and see, smell and feel that different grain.

It began raining while I was milling the oak and I was able to shelter and move tools into the falling cabin, but the wet oak was harder to mill after that. I think the chain needed sharpening at this point too. Ripping chains dull quicker than regular cross cut chains because they are tearing through more lumber for a sustained time.

On my next trip back I’ll try out another time saver: I’ll get a ripping chain for my smaller saw and see if it has enough power for the vertical, Timber Tuff cuts. If it does I won’t have to change out the big saw from the Alaskan Mill.

I’m one step closer to believing in the viability of milling my own wood for the cabin project and doing it with my own labor. I need more practice with the Alaskan Mill, but I’ve gotten over the hurdle of using it for the first time and don’t feel overly intimidated.

Along with this big step forward in logistics I got some other work done. I cleared the oak tree limbs off the fallen cabin and put out a large stack of free firewood from the pieces that I chainsawed.

I did the biannual clearing of trails.

I moved five large brush piles off the cabin site into the woods. In the process I’m providing homes for wild animals that might like to move into the heaps of sticks and leaves.

The most immediately satisfying thing I did was replace almost a whole half of the corrugated tin roof of the shed with clear, polycarbonate panels that let light in. The shed has been a dark, somewhat scary dungeon filled with very large fishing spiders, wasps, evidence of mice and, I imagine, the occasional resting place for snakes to curl up. My previous attempt to light it with battery operated camping lanterns was a failure. Most often I just used my phone to spotlight around the room. These panels have brought natural light in. Now I can see every corner of the place without fear that reaching for a hammer might mean grabbing hold of something that will make me scream.

There was evidence of more snakes. This skin was found not far from my previous snake sighting on the cabin site and this small snake at the falling cabin.

I want to amend my previous idea that the black snake I saw earlier was a black racer. I now believe it was a rat snake. I found one newly killed on the road. Its black was similarly lustrous and it seemed about the same size. The belly was completely white — a part I couldn’t see on the live snake.

I was very happy that my old college friend Julie and her husband Dave came for a visit and that I got to show them the land. We picked raspberries and walked through the woods. Julie used her bird call app on her phone to identify several birds including a Pileated woodpecker. Birds are hard to see during summer in these woods because of the amount of leaf cover. Pileated woodpeckers are so cool and I’m happy to know at least one might be hanging around. Here we are sitting on my new bench:

…………………………….

I’d like to end this post with an anti-sentimental song that I found to be absolutely gorgeous and moving. As I was driving back and fourth to the land I found a fantastic radio station, WDVX, out of Clinton, TN.

One morning I was listening and I heard this song, Last of the Better Days Ahead, by Charlie Parr. Maybe because I was a week away from turning sixty and was thinking a lot about Stewart who had died and how you never know how many days you have left…maybe also because I had really stupidly backed into my cousin’s car and done over ten thousand dollars worth of damage and was focused on the money that I’d have to shell out for my increased insurance premiums along with the extra hassle I’d created for people…

this song broke through all that and made me ponder what is most important…

If you clink on the link below, then the black arrow on the Bandcamp website you can hear this beautiful song.

https://charlieparrmusic.bandcamp.com/track/last-of-the-better-days-ahead